Technical Information - GSI Coiled Duct

GCD vs Traditional Duct Key Differences

171103 GCD vs Traditional KEY DIFFERENCE[...]

Adobe Acrobat document [143.7 KB]

171103 GCD vs Traditional KEY DIFFERENCE[...]

Adobe Acrobat document [143.7 KB]

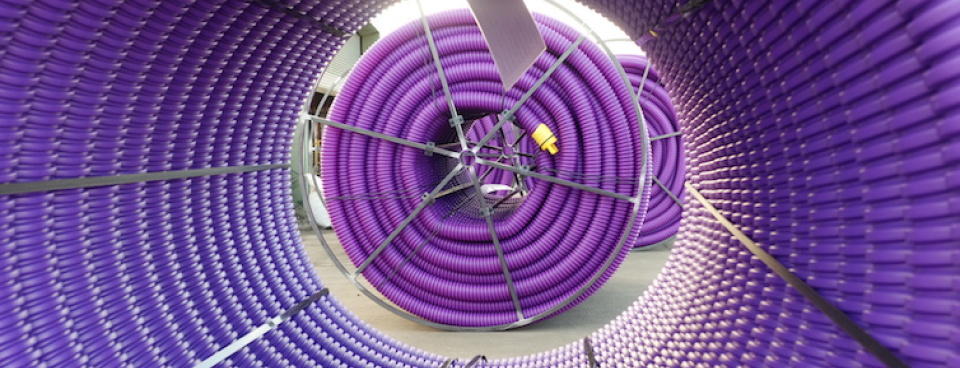

GCD Presentation and Pictures

171113 GSI General Presentation 2017.pdf

Adobe Acrobat document [1.6 MB]

171113 GSI General Presentation 2017.pdf

Adobe Acrobat document [1.6 MB]

Compression Strength: up to 3,100N

Tensile Strength: up to 321Kgf/cm2 (at 5% deformation of outer diameter)

Heat Resistance: 0.4% (at 110C)

Thermal deformation: 3%

Friction Factor: 3%

Heat Transforming Factor: <3% after storing for 60 minutes at 110C

Impact Test: Passed - free from distortion and tear

Bending Performance: Bendable to -20C

Electrical: Withstands AC2,000V over 15 minutes

Insulation: Over 100MΩ

Chemical resistance no defects at:

40% HNO3

40% NaOH

30% H2SO4

10% NaCl

Tested and compliant with IEC 61386-21, IEC 61386-22, IEC 61386-24

Some possible configurations of GSI Coiled Duct. Standard production items are highlighted in red:

|