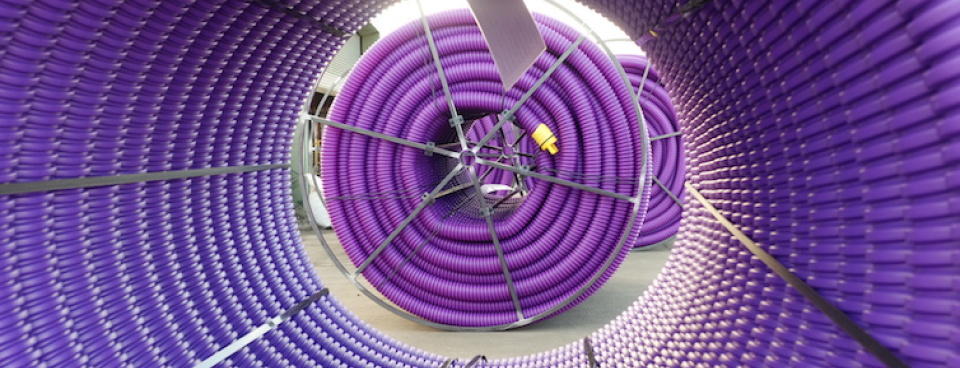

GSI Coiled Duct (GCD) is a very robust continuous coiled duct solution for cable protection on infrastructure projects. GCD is manufactured from high density polyethylene (HDPE) in long continuous lengths with integral inner ducts. Inner ducts can also be silicone lined. GCD is a complex extrusion and the inner ducts are welded to the outer duct throughout its length. As a consequence the inner ducts form part of the structure and cannot free float. The result is a duct with unparalled strength.

In comparison with traditional duct solutions, GSI Coiled Duct offers excellent strength and flexibility. GCD has solved problems associated with compressive load. GCD has greater flexibility, reduced weight, greater continuous lengths, high reliability and greater cost efficiency. GSI believe that GSI Coiled Duct is the best cable protection duct solution available.

The recommendations from a UK industry report for UK Highways reports:

- "Permit/encourage use of this duct on all future schemes including technology on a wide scale";

- "GCD should be utilised going forward - not as a departure from standard but as an alternative or de-facto standard".

The following document outlines the key differences between GSI Coiled Duct and traditional ducting:

The strength, design and simplicity of GSI Coiled Duct enables great lengths of underground cable protection infrastructure to be installed very quickly. This delivers significant cost savings and more duct can be laid in a given time than was previously possible.

In the UK, a large customer has assessed that a current 29 week project could be delivered in 6 weeks with GSI Coiled Duct, with Health & Safety risks reduced by up to 89%.

GSI has also shown how installed costs can be reduced by >18%.

for example: A project costing £300k for traditional duct can save at least £53k by using GCD.

GSI Coiled Duct does not require additional chambers to accomodate changes in elevation or direction. This generates further savings.

GSI Coiled Duct also generates efficiencies in the amount of cable carried - typically 5% less cable is required. Future maintenance costs will also be substantially reduced.

Significant environmental and and social benefits result from this cable protection duct infrastructure. The speed and simplicity of installation results in reduced disruption to traffic. Substantially reduced working time in hazardous areas produces substantial Health & Safety benefits.

There is no requirement to import large amounts of protective layers of aggregates/gravel during installation. Several environmental impacts result: less material requires transportation, less waste soil disposal and fewer materials require storage.

The benefits of GSI Coiled Duct are also long term. Ongoing repair and maintenance costs to the duct infrastructure will be significantly reduced. Future improvements and upgrades due to technological advances can be adopted with ease.

The outer diameter of GSI Coiled Duct can range form 50mm to 160mm. The cable duct can be manufactured with up to 9 inner ducts of multiple colours according to the customers design.

GSI Coiled Duct General Specification 18[...]

Adobe Acrobat document [384.0 KB]