Health & Safety is one of GSI's key corporate values.

GSI are focused to ensure the safety of our own staff in the work environment and we work with our customers to reduce Health and Safety Risks in their working environment too.

Speed

Traditional duct is currently installed at an average rate of 150m per day. GSI Coiled Duct can be easily installed at 1,000m per day. This enables projects to be completed more quickly and reduces the time spent by operatives in high risk working environments. Actual unspooling 600m of duct takes approximately 15 minutes. There is minimal manual handling of duct.

Strength

GCD is significantly stronger than traditional duct. GCD has been tested to IEC 61386 to have a compressive strength in excess of 2,500N. As a result, GCD can be installed simply using graded 'as dug' backfill.

Trenches

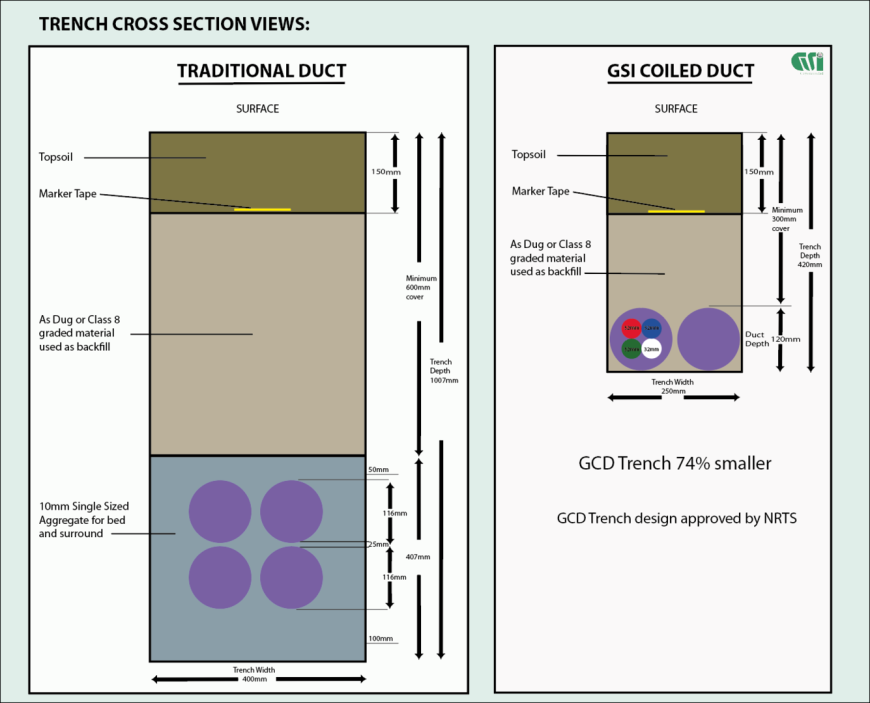

Due to the strength of duct, GCD can be installed at much shallower depths than before. Trenches are a high-risk environment. With GCD, trenches can be 74% smaller than traditional trenches and are therefore faster to create and safer. Workers do not have to work in trenches to install GCD. No special aggregates need to be imported to site. Graded 'as dug' soil is used to fill the trench.

Reduced Man Hours

GSI Coiled Duct (GCD) reduces the time spent working in a High Risk environment.

For a 20Km scheme @ 720m/day, man hours can be expected to reduce by 4,167 hours

Safer installation

The installation of GCD is largely mechanical. There is little manual handling from chamber to chamber.

Traditional duct requires much higher manual handling. Traditional ducts have to be laid out along the route in preparation for installation. Workers have to work in trenches to join multiple sections of traditional duct together at every 6m. These joints then have to be air tested.

Air-Testing

GCD is air-tight by design. GCD is very robust with high strength. GCD has no joins and delivers single continuous duct connections from one chamber to the next. GCD can remove the requirement for air testing and it is now possible to install main longditudinal GCD ducts without a requirement for air testing.

Traditional duct requires joins every 6 metres. Every join requires men working in the trench and every traditional joint is a potential point of weakness, both now and in the future. Air testing traditional duct has to be carried out in the trench.

Traditional duct needs to be air-tested every 6m or 12m. Each test takes 20 minutes in a high-risk environment.

For example:

Over a short 100m section, GCD removes the requirement for at least 8 testing processes on a single duct, saving over 4 hours of testing - saving time, money and greatly reducing health and safety risks.

Fewer vehicle movements

Fewer vehicles are required to transport materials, making for much safer, more cost effective and less congested roads and work sites, which also has a positive impact upon the environment.